You need a valve to control the flow of fluids, right? But then, there are lots of different types you could choose from. Because of this, choosing the right valve can sometimes not only be time-consuming but also confusing and tiring. If you are in a tight spot where you have to choose a valve and it's your first time doing so, it's important to catch up on the basics of your system requirements. This, as you will find out will make things easy for you.

With that out of the way, here’s a list of things that you should adhere to when choosing a valve.

The type and size of the valve

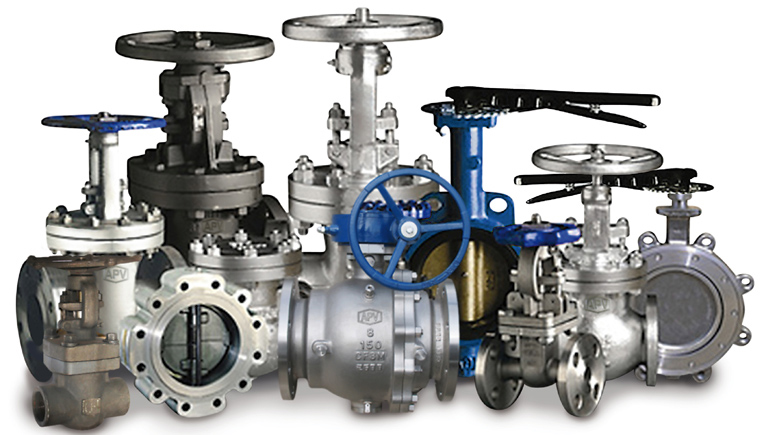

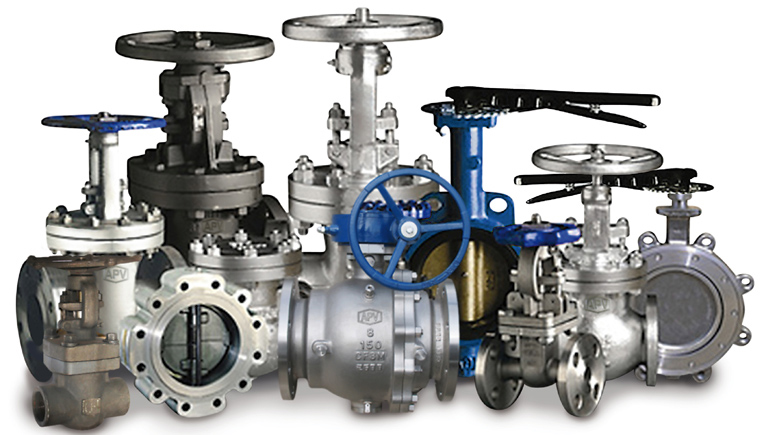

Normally, most valves perform more than one of the basic valve functions (shutting off flow, diverting the flow, mixing the flow, prevention of backflow, or relieving pressure). To achieve either or some of these functions, you can choose between the ball valve, gate valve, check valve, trunnion valve, globe valve, trunnion, Y strainer, or the coupling valve. Just choosing either of these valves, however, won’t do the trick, they need to be correctly sized as well.

Performance requirements

Just picking out the correct valve won’t do the trick when it comes down to performance. You need to decide its pressure and temperature requirements. Normally, metallic valves have got a higher tolerance for pressure and temperature as compared to the plastic ones. As such, if you are working with pressurized fluids or anything else, metallic valves are the way to go. I'd recommend that you only go for plastic valves if you need to.

The build quality

Being the top

valve supplier usa, we are quite watchful of the materials used in manufacturing our valves and so should you. Depending on the nature of the fluid, you should be able to know the chemical compatibility it will have with your valve. Whereas plastic isn’t great for extreme temperatures or pressure, it’s the go-to option if you’ll be dealing with corrosive fluids.

The valve maintenance

Regardless of the kind of valve you have installed or are planning to install, always remember that they do need ongoing maintenance. After all, this is what ensures the valve is reliable and the system is stable. Also, the type of valve connection you have (whether threaded, push-in, Luer, barbed, etc.) has its advantages and disadvantages. It is therefore important that you determine the best connection type for the kind of valve you have installed.

Always remember that check valves are a little more demanding than other valves

To ensure a new check valve has an optimal operation, pay attention to both the response time and the pressure needed to open the valve.

Additionally, …

There’s a difference between normally open and normally closed check valves. The latter need positive pressure downstream to remain open. The other designs, on the other hand, need positive back pressure to close. Since these two can’t be used interchangeably, you should pick one based on whether or not the valve should be open more or closed more when your system is operating normally.